Powering Batteries with Graphite

It is the largest battery material component in the battery. The morphology of graphite allowed researchers to create anodes with a higher rate capability and energy density. 42% of all battery anode material is sourced from natural spherical graphite, 58% from synthetic graphite material. The demand for graphite is set to increase by over 200% in the next four years.

70000

TPAOverall Output by 2026*

78

%

Global Warming Potential

25340

TPATotal Annual Capacity

“Lowering battery costs is crucial in making electric cars more

affordable since the battery pack

accounts for half of the purchase

expense, with the cells making

up 70% of the cost, the graphite

anode 15%.”

Vikram Handa

Founder & Managing Director

Crafting Diverse Anode Materials

Synthetic, Natural, Blended & Agglomerated Graphitic Innovations with Special Epsilon Advantage

High Perfomance

Unleashing the full potential with our optimized anode materials, amplifying battery efficiency and performance.

High Capacity

Experience extended range and increased productivity powered by our high-capacity anode material. Minimum requirement for EV grade anode is 345-350 mAh/g, ours is at 362 mAh/g.

High Quality

Our materials undergo rigorous testing, ensuring higher quality for reliability, durability and safe batteries.

Longer Life Cycle

Battery materials designed to last, reducing the need for frequent replacements.

Fast Charging

Powering up devices with our material’s fast-charging capabilities, maximum output with minimum input.

Value Driven

Proprietary, advanced, and sustainable processes, sourcing locally while supplying globally, ensures exceptional value.

Greenest Materials

Powering industry with our greenest materials, making a substantial ~78% reduction in global warming potential (GWP) compared to competitors.

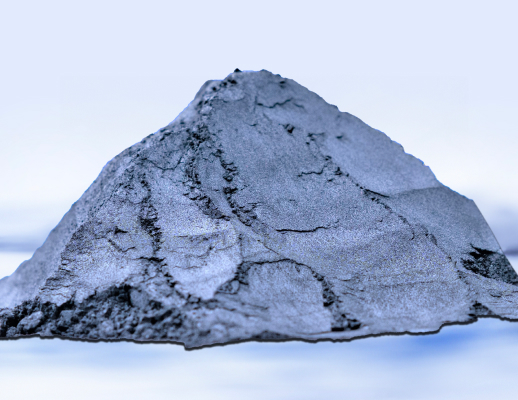

Epsilon Mesophase Coke

Epsilon Mesophase Coke (EMC) is a premium raw material used by anode manufacturers offering consistent quality and high performance. Highly Epsilon Mesophase Coke (EMC) is a premium raw material used by anode manufacturers due to its consistent quality and high performance. Our differentiation is the degree of customization, and technical specifications as per customers’ requirements giving different particle sizes, volatile matter and shapes as per their requirements. read more

Epsilon Mesophase Graphite

Epsilon Graphitized Natural Graphite (EGNG) anode requires experience and expertise in processing of natural graphite flakes in an Epsilon Mesophase Graphite (EMG), A synthetic graphite anode highly customizable, meeting specific requirements suitable for high-power cells and long-cycle cells. read more

Epsilon Graphitized Natural Graphite

Epsilon Graphitized Natural Graphite (EGNG) anode requires experience and expertise in processing of natural graphite flakes in an environmentally. Epsilon Graphitized Natural Graphite (EGNG) anode has the required experience and expertise in processing natural graphite flakes in an environmentally friendly thermal treatment process to meet battery-grade specifications. read more

Epsilon Mesophase Coke Powder

Epsilon Mesophase Coke Powder (EMP) is a unique product used for direct graphitization. Helps anode makers lighten the process and Epsilon Mesophase Coke Powder (EMP) is a unique product used for direct graphitization. Helps anode makers lighten the process and improve their carbon footprint. Is highly customizable, providing particle sizes, volatile matter and shapes as per the customers’ requirements. read more

Epsilon Synthetic + Natural Graphite

Epsilon Synthetic + Natural Graphite (ESNG) anode is a blended graphite that is highly customizable and benefits of high Capacity Epsilon Synthetic + Natural Graphite (ESNG) anode is a blended graphite that is highly customizable and has the benefits of high capacity of natural graphite with the better rate performance of synthetic graphite. This material reduces the overall processing time for making anodes. read more

Silicon Carbon Compose

Silicon Carbon Compose (SI-C) Anode with the right blend of silicon has a high theoretical lithium storage capacity and is the new frontier Silicon Carbon Compose (SI-C) Anode with the right blend of silicon has a high theoretical lithium storage capacity and is the new frontier in the development of high-performance batteries. Epsilon Agglomerated Graphite (EAG) A synthetic graphite anode meeting specific requirements suitable for high power and EV sector. read more

Epsilon Agglomerated Graphite

Epsilon Agglomerated Graphite (EAG) A synthetic graphite anode meeting specific requirements suitable for high power and EV sector.

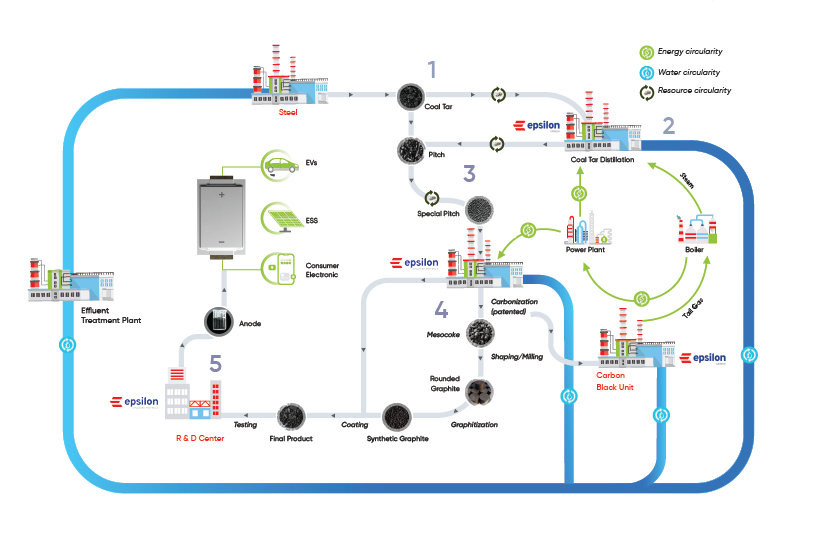

Case Study

Building without emissions and manufacturing with waste materials

Step 1

Our manufacturing process utilizes a by-product derived in the manufacturing of steel as a key raw material. We distil this to manufacture Coal Tar Pitch and a variety of intermediate chemicals.

Step 2

The Carbon Black Oil produced as a by-product in the Coal Tar Distillation process is used as a fuel and feed for the Carbon Black production process within our facility.

Step 3

The Coal Tar pitch is further processed to produce Impregnation pitch. Through the thermal process, we convert the impegrnation pitch into meso coke. A high performance anode pre cursor with unique properties.

Step 4

Through our patent-pending technology, we produce high-quality, high -performance, synthetic graphite anode material for Lithium-ion Batteries in an eco-friendly manner using shaping/milling/granulation/thermal purification and coating processes.

Step 5

We also have a range of designed instruments in-house for testing capabilities for single pouch cells that can test first-cycle discharge capacity, efficiency, and the spring-back nature of materials.