Powering Batteries with LFP Technology

In a LFP battery, Lithium Iron Phosphate is the cathode material while graphite carbon forms the anode for the LFP battery. There are other types of Lithium-ion batteries in the market such as Lithium Cobalt Oxide (LCO), Lithium Nickel Manganese Cobalt Oxide (NMC), Lithium Titanium Oxide (LTO) but the LFP battery stands out in terms of safety, longevity, sustainable sourcing and cost-effectiveness. These attributes also make LFP batteries the ideal choice for Energy Storage Systems and EV applications. Technology improvements and cell to pack advancements have realized parity with NMC batteries. LFP is the fastest growing cathode material and is set to play a big role in the transition to clean energy.

“At Epsilon, we envision a world powered by sustainable energy alternatives. Our advancement in anode research and manufacturing was a first step, and with company venturing into cathode reaffirms our commitment of serving global players with sustainable and reliable battery materials. Epsilon becomes first global company capable of providing manufacturers with cathode and anode materials for lithium-ion batteries, which is poised to make India the first country in Asia outside of China to manufacture LFP (Lithium Iron Phosphate) cathode materials.”

Vikram Handa

Founder & Managing Director

Innovative Cathode for LFP batteries

Safety

LFP batteries are among the safest types of lithium-ion batteries with a low risk of overheating and catching fire. These batteries are less prone to thermal runaway and do not release oxygen if they catch fire, making them safer than other lithium-ion batteries.

Long- Life Cycle

LFP batteries have a longer lifespan than any other lithium-ion batteries due to their low degradation rate. They can be charged without significant battery damage therefore leading to longer lifespan.

Cost Effective

The materials used to produce LFP batteries are relatively cheap compared to other lithium-ion batteries. The main cathode materials used in LFP batteries are iron and phosphate and they are in relative abundance in contrast to other battery materials. This makes them a cost-effective option for a variety of energy storage applications.

Environmentally Sustainable

LFP batteries are environmentally sustainable because they are non-toxic, and do not contain harmful heavy metals. The absence of cobalt in LFP means they can be much more ethically sourced than traditional lithium-ion batteries. Even when they eventually wear out, investments in lithium battery recycling have diminished their negative environmental impact. Recycling allows for the reuse of internal components.

LFP Cathode Material For Power & ESS Applications

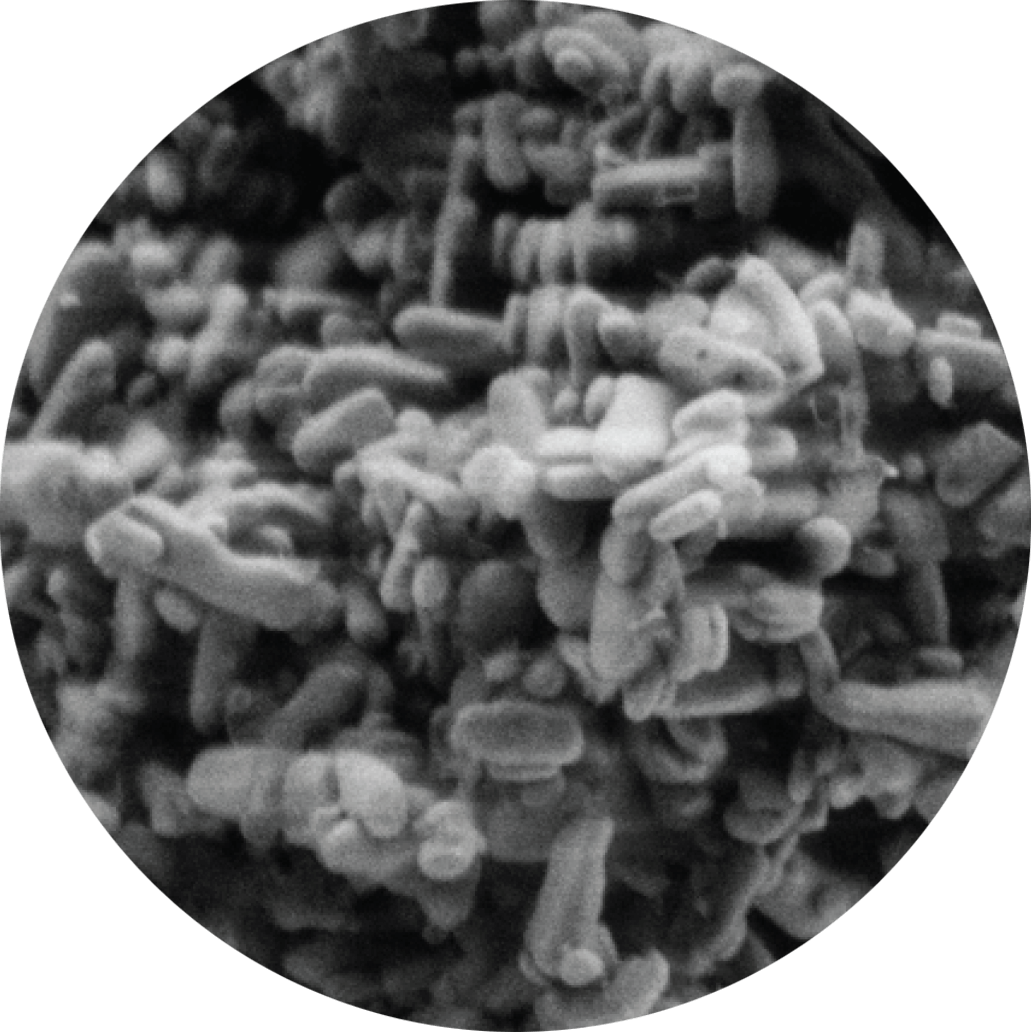

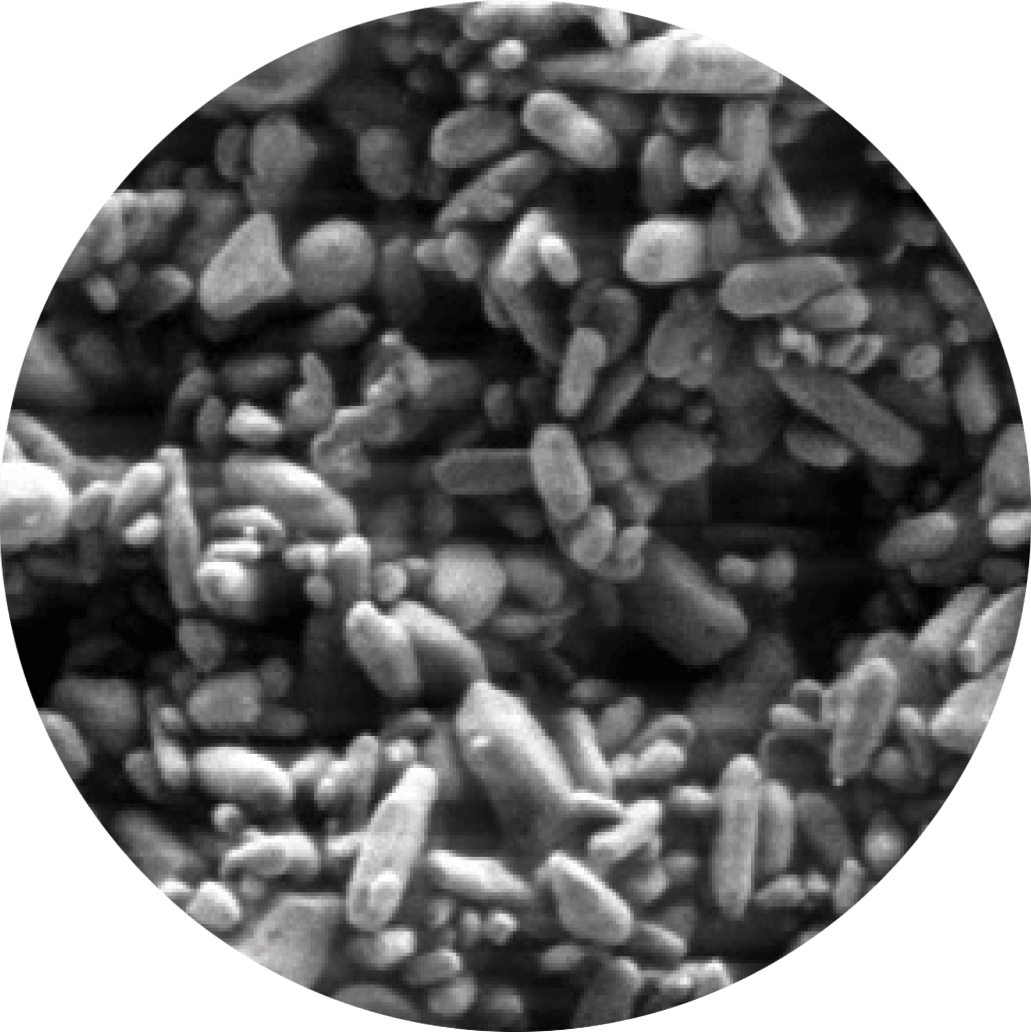

E-P2

Application: PHEV and 12V starter

- Single crystal morphology

- High-rate performance

- Suitable for thin electrodes

- Excellent low-temperature performance

- Particle size D50* - 0.3 - 0.6 µm

- C/10 capacity** - >158 mAh/g

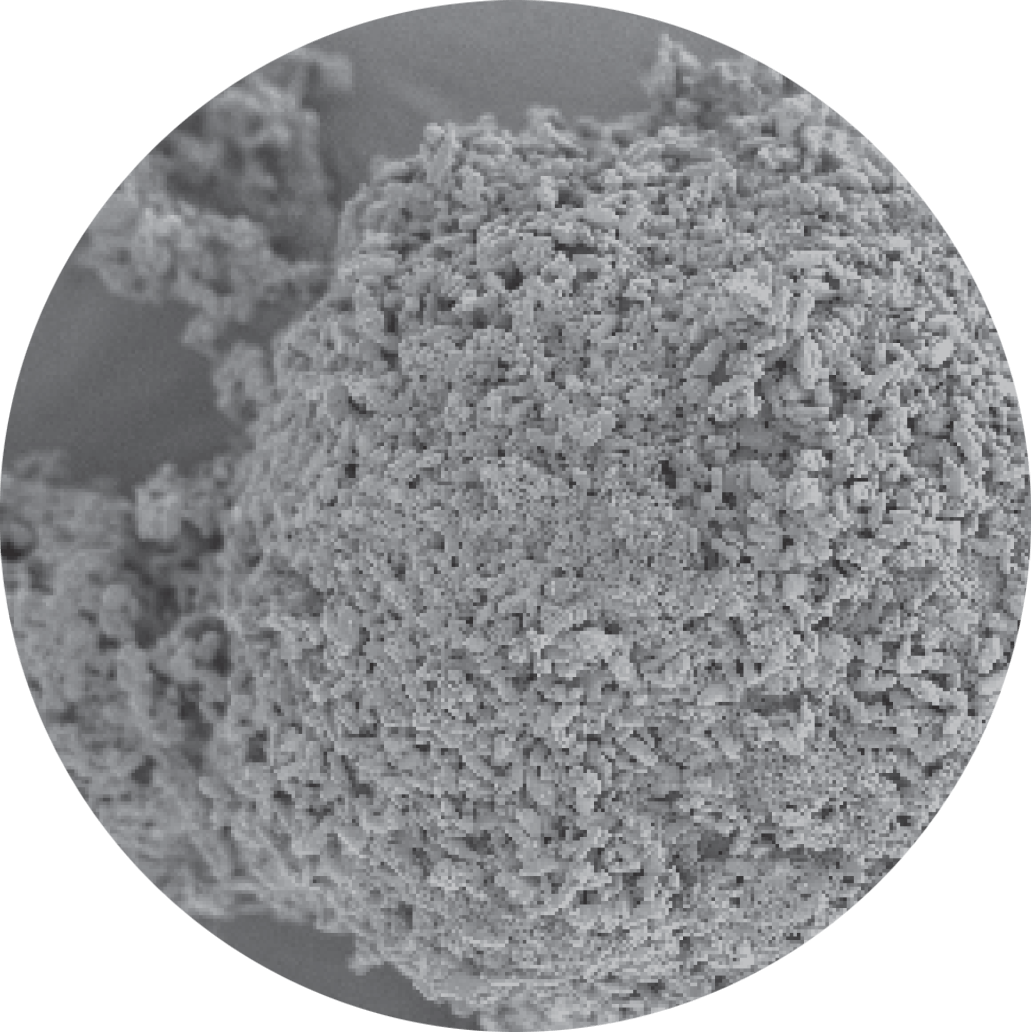

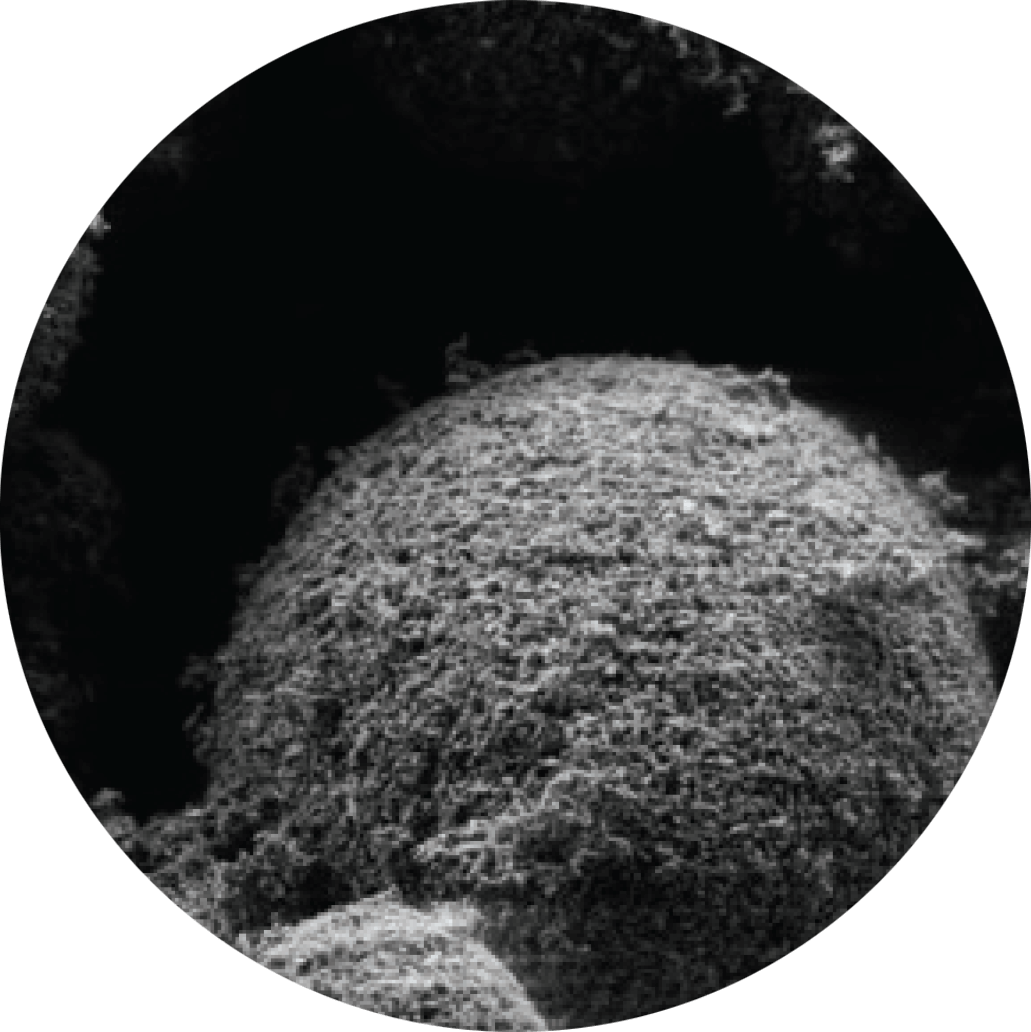

E-P2S-UF

Application: Mild Hybrid, 12V starter

- Spherical agglomerated morphology

- High-power

- Low impedance

- Low-temperature. Performance to -30°C

- Particle size D50* - 8 - 15 µm

- C/10 capacity** - >158 mAh/g

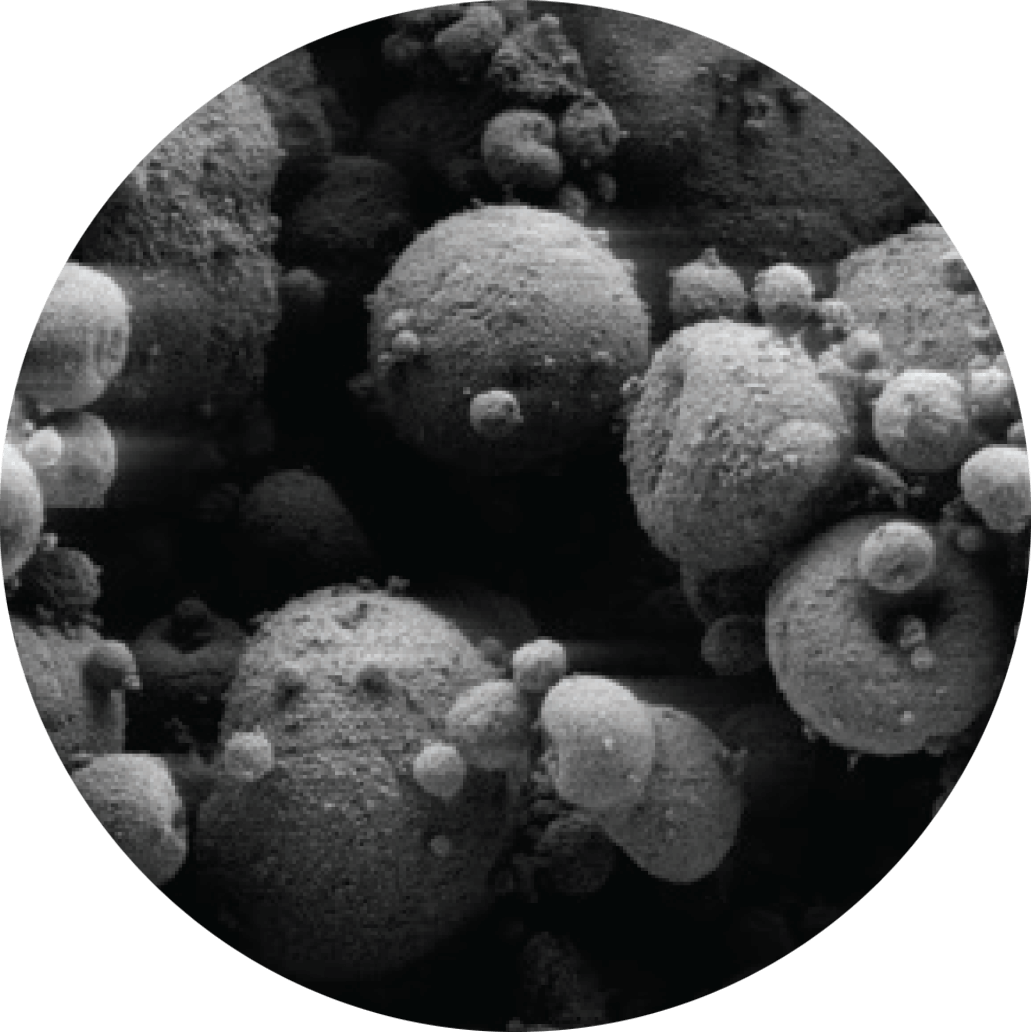

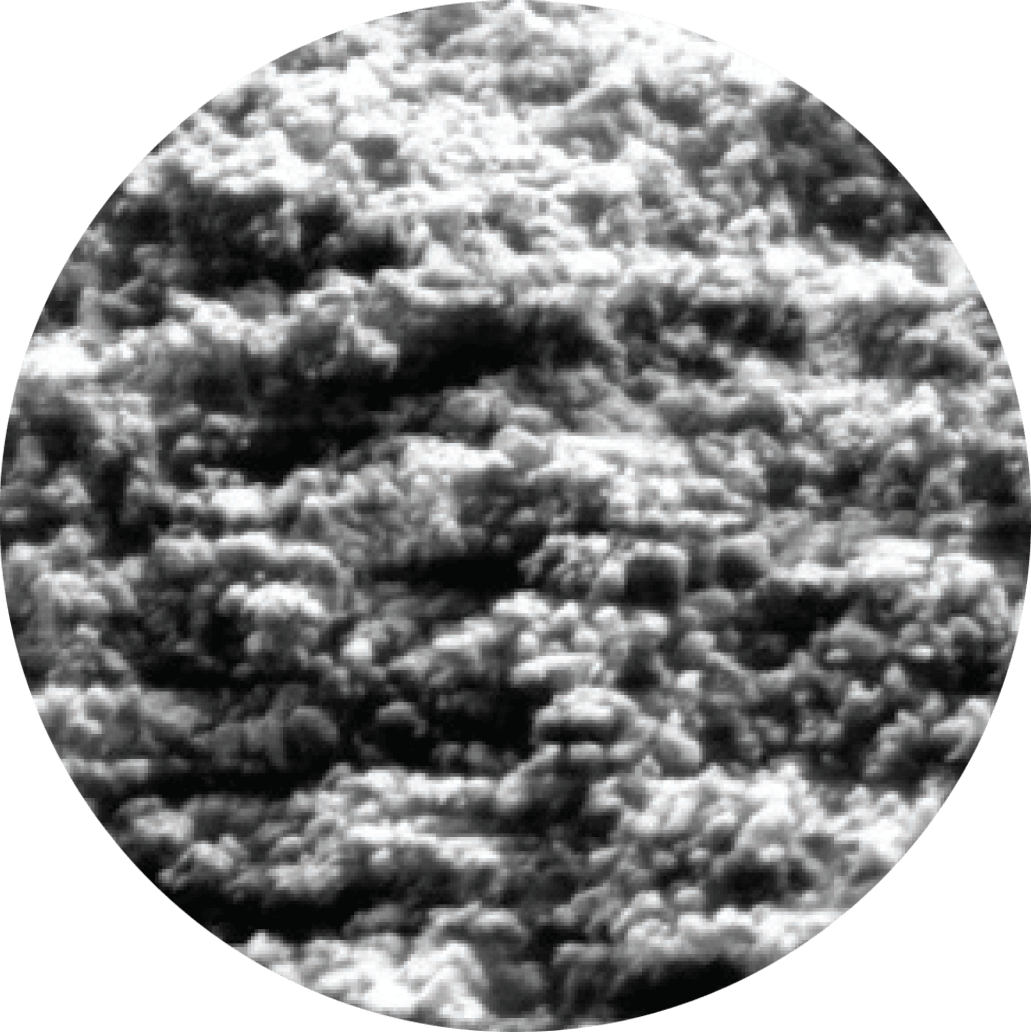

E-P2S2

Application: PHEV, Mild Hybrid

- Spherical agglomerated morphology

- High-power

- Low polarisation

- Low cell impedance

- Good processability

- Low-temperature performance

- Particle size D50* - 7 – 13 µm

- C/10 capacity** - >155 mAh/g

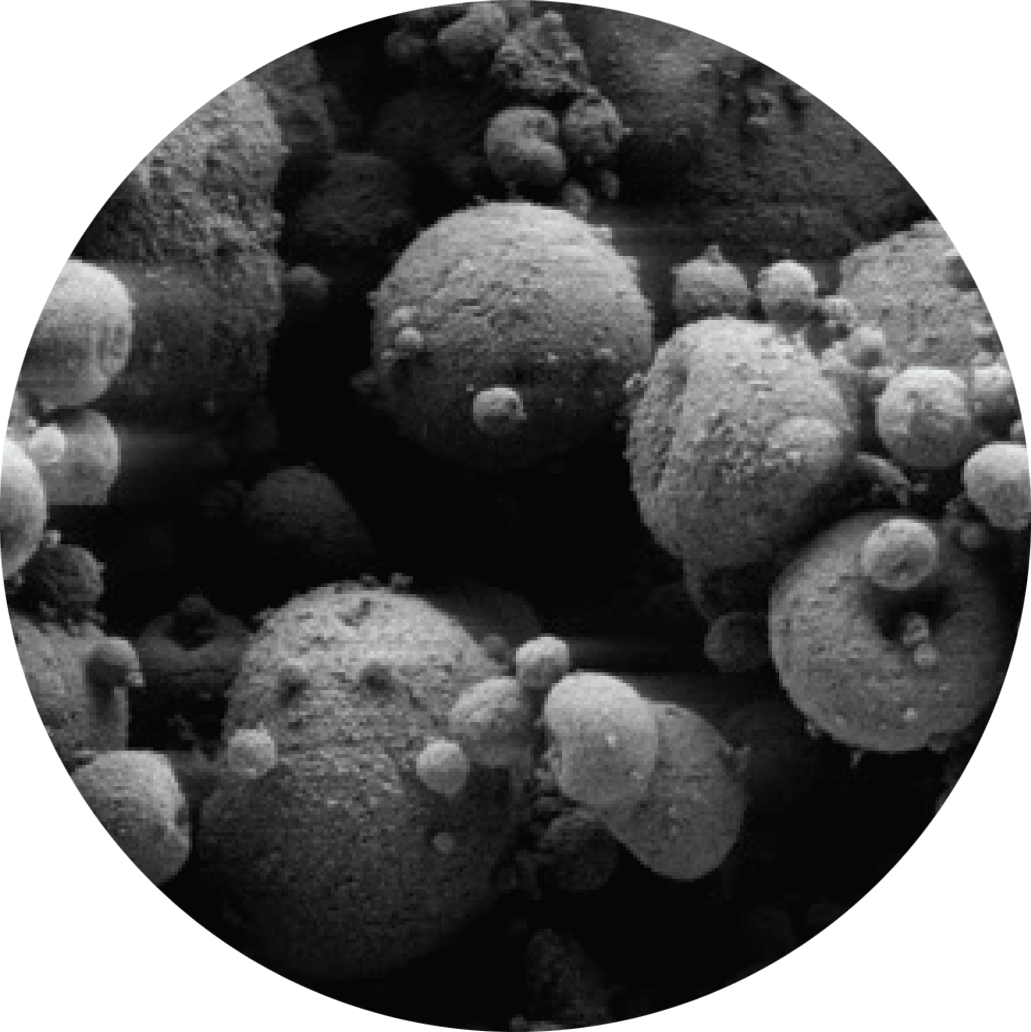

E-P2E

Application: BEV and ESS

- Single crystal morphology

- Medium power performance

- Easy compression

- Excellent low-temperature performance

- Particle size D50* - 0.4 - 0.7µm

- C/10 capacity** - >157 mAh/g

E-P2S

Application: ESS, BEV and PHEV

- Spherical agglomerated morphology

- High performance & Energy density

- Low polarisation & low cell impedance

- Low-temperature performance

- Energy density to improve by using

- P2S/P2- blends

- Particle size D50* - 11 – 16 µm

- C/10 capacity** - >158 mAh/g

LMFP Cathode Material For Power & ESS Applications

E-M2

Application: BEV and ESS

- Single crystal morphology

- Particle size D50* - 0.5 – 5 µm

- Surface area (BET) – 26 - 36 m2/g

- C/10 capacity** - 148 mAh/g

- 4C capacity** - 134 mAh/g

E-M2S

Application: BEV and ESS

- Spherical agglomerated morphology

- Particle size D50* - 7 – 14 µm

- Surface area (BET) – 23 - 33 m2/g

- C/10 capacity** - >148 mAh/g

- 4C capacity** - 132 mAh/g

Case Study

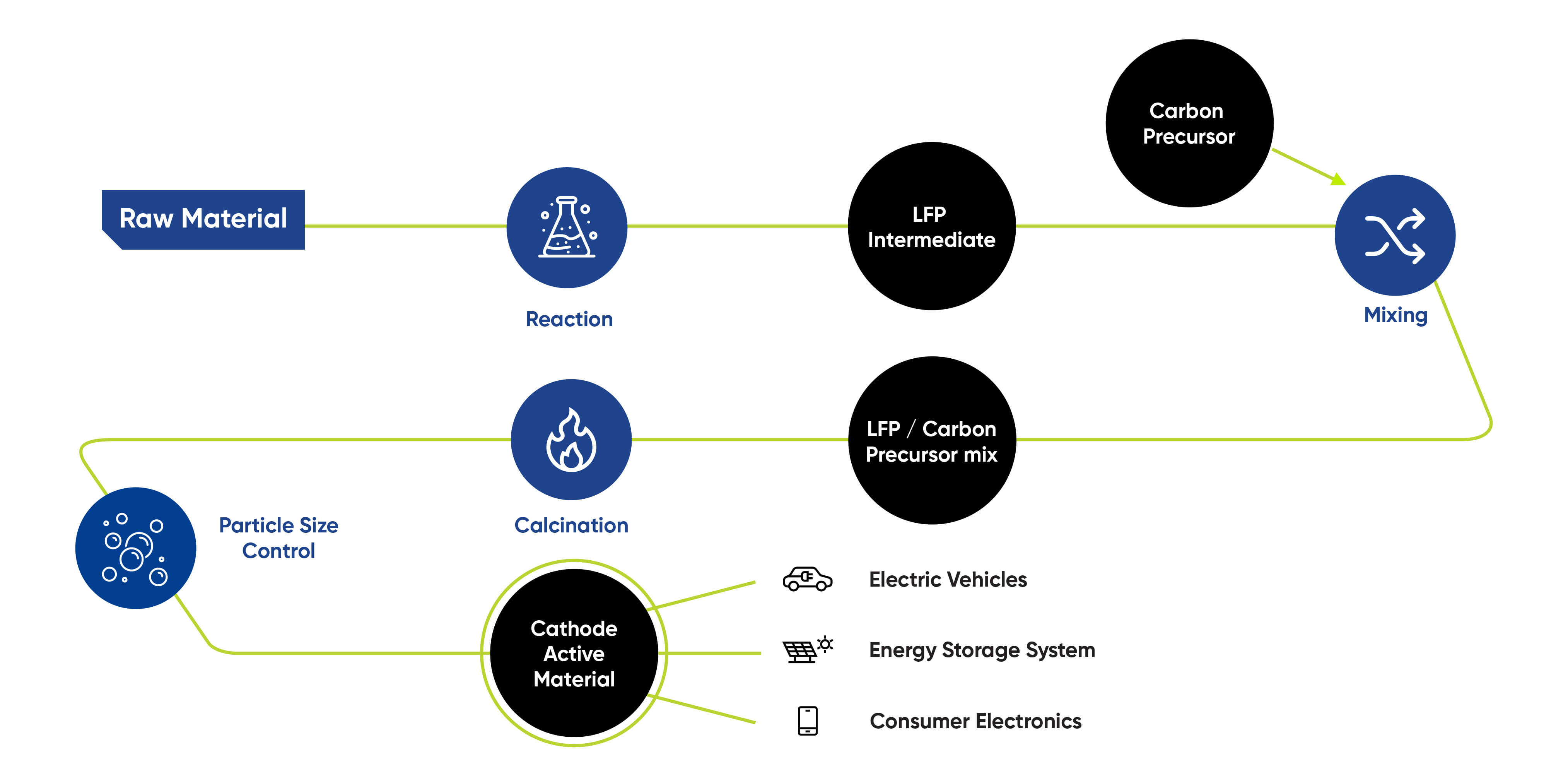

Epsilon Cathode Process

Step 1

Our manufacturing process utilizes a by-product derived in the manufacturing of steel as a key raw material. We distil this to manufacture Coal Tar Pitch and a variety of intermediate chemicals.

Step 2

The Carbon Black Oil produced as a by-product in the Coal Tar Distillation process is used as a fuel and feed for the Carbon Black production process within our facility.

Step 3

The Coal Tar pitch is further processed to produce special pitch. Through the thermal process, we convert the special pitch into meso coke. A high performance anode precursor with unique properties.

Step 4

Through our proprietary technology, we produce high-quality, high-performance, synthetic graphite anode material for Lithium-ion. Batteries in an eco-friendly manner using multi stage process which involves mechanical process and thermal process.

Step 5

We have a full-fledged lab equipped with special instruments for powder and cell testing.